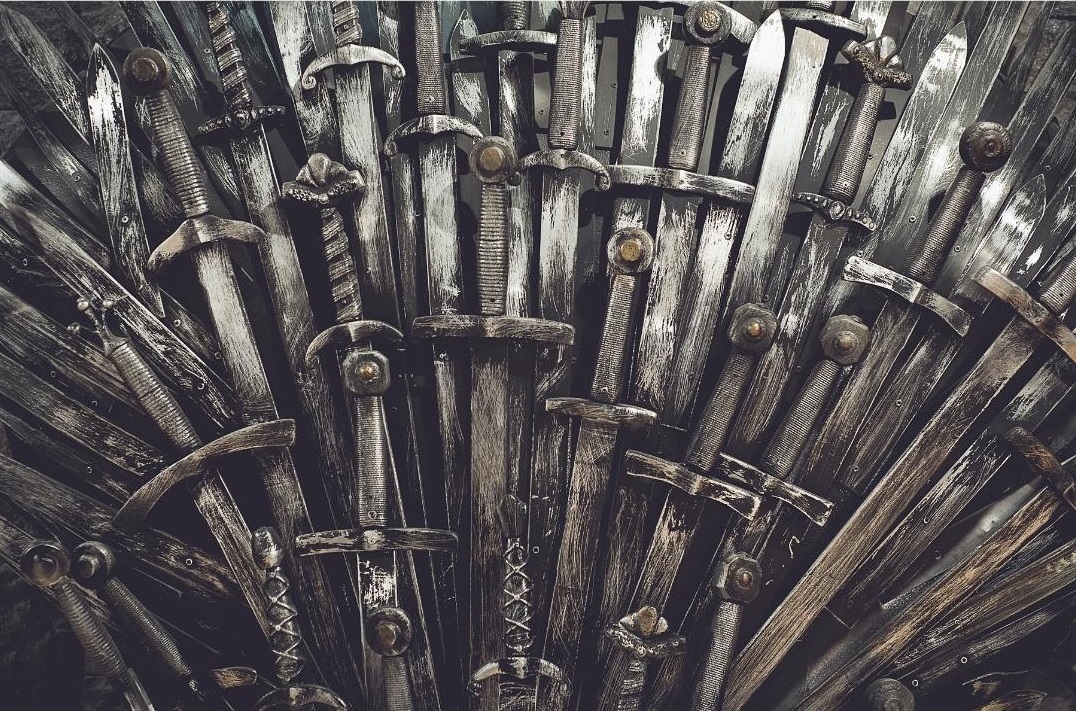

Did you know that the name steel comes from the Latin aciarius, which refers to the material from which bladed weapons were made in ancient times? Yes, it is believed that shortly after 3,000 BC the possibility of mixing iron with other metals to make new materials was discovered.

Although the first evidence of wootz steel (primitive steel with high hardness and high carbon content) dates back to 300 BC and was found in India.

Later, with the advent of industrialisation, many scientists and industrialists became interested in obtaining steel, thanks to the use of electricity to heat furnaces in order to melt iron with other elements and create steel.

But how was it created?

Steel was discovered by chance.

They were not aware of the new material they were creating, but they were aware that the iron they were creating was harder and stronger. Thus, was born the first research work on steel.

And during that research came the discovery of the alignment of iron and carbon, what is known as steel.. This new material was a great discovery for mankind and became the material of choice for armour and weapons because of its advantages over iron.

The problem? It was difficult to make because it took a long time to produce in small quantities.

Until the engineer Henry Bessemer revolutionised the manufacture of steel by making it easier to make.

He created a converter called “The Bessemer Converter” which converted pig iron into steel. This converter consisted of a steel boiler on the outside and a material that could withstand heat and fire on the inside.

With this invention, steel could be produced in larger quantities and in less time.

And today, how is it made?

Nowadays, the technique for obtaining steel includes various metals that give it hardness and strength.

Furthermore, the process involves what is known as secondary metallurgy. This second stage gives it the chemical properties and the desired level of inclusions and impurities. The usual steelmaking procedure involves the addition to the iron of an amount of carbon not exceeding 2 %, depending on the degree of hardness to be incorporated into the steel.

Also, another way of making steel is by recycling by melting down scrap made from steel. Its use today is very extensive as it is used to manufacture various objects or even to construct buildings.

Did you find what we have told you about steel interesting?